by Howard Johnson

They were years of hard work, 1946 to 1956. Charley Wingo, Ed Hewitt and Charles Abramo transformed the remains of Allied Aviation into Molded Products, Inc. They moved all the equipment 3 times, put 35 friends and family to work, built pontoon bridges, medical boxes, air rescue boats, canoes that weighed 37 pounds, small sailboats in fleets, for the Navy, larger 24’ sailboats for Luders, in Mass. and Navy lifeboats. They went to the NY boat show every year, signed up 40 dealers, nationwide. They set up shop in rented barns near Williamson Veneer in Cockeysville, MD.

They designed and built several dozen solid wood mandrels on wheels and then molded thousands of boats off of them, baking each until rock solid, in the 30 ft long steel autoclave oven powered by 250 lbs of steam and 150 lbs,vacuum.

They set up and ran a lumber mill, a huge veneer coating department, cutting and shaping departments, assembly rooms and a painting and finishing room.

The three founders worked most weekends improving every aspect of their operation. Designs were constantly critiqued and improved to keep up with the market. Hardware, fastenings, tools, construction methods and advertising steadily evolved over time. Charley Abramo often traveled to Philadelphia, to the Thompson Lumber Co., where he selected the finest, knot free, straight grain mahogany. The record largest board brought by train was 21ft. long 25” wide and 6 inches thick. They were flooded out 3 times and finally bought 3 acres nearby on York Road, the edge of a farm, for $1,000.00 per acre.

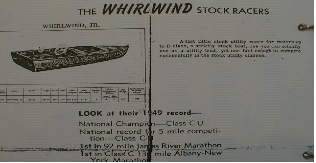

They modified their designs and went racing, everyone participated and all had some measure of success. Charley won first, second, and third prizes in a dozen races during the `46 to `49 era. They even sold cut down, stock racing models. Their successes made all the local papers.

They worked all year around, renting local barns and stacking piles of boats for spring and summer sales. The third Charley, – Charles Martin, drove a Chevy heavy duty pickup with a special trailer they built, that could haul 8 boats at a time. He delivered boats throughout the year to dealers all around the United States. Each one was his baby: he kept touch-up paints and varnish on board and made sure every one was perfect before the papers were signed. Once, several boats flew off the top in a huge storm. He took them back to the factory where they were repaired good as new. Since the factory was flooded out 3 different times, all employees were involved in the cleanup operation. It was a great relief to finally move into the new buildings on York Road.

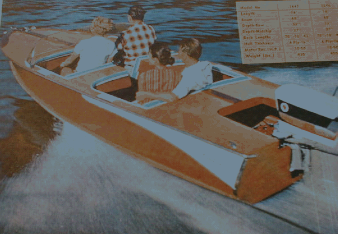

They shipped boats unfinished for do-it-yourselfers, they painted or finished for individual tastes, models were just plain wood or fancy padded and upholstered with blonde decks called avoirdire, – for magazine covers.

A tiny promotional tugboat for kids was made in limited production.

A custom, double ended Cleopatra’s Barge was made for a special customer.

They had a Montgomery Wards contract for Sea King boats, 300 per year were set aside for spring with the special trim. Every year new models and designs were offered to keep the line fresh. Dealers would sell remaining stock as “new”, each succeeding year, a nationally accepted practice. Employees appeared in all ad photos, color was used for the first time when they could afford this luxury.

In 1956 their New York Boat Show visit revealed that changes were sweeping the industry. The narrow, early models needed to be redesigned. For 1957 wider, more family friendly hull widths were introduced. The whole Molded Products Inc. line was changed. Wrap around windshields, solid floorboards, more bow flair and sweeping painted side trim. All bottom colors were now white, hulls used more layers of veneer, fancy new hardware and steering wheels and bigger engine capacity.

In `58 and `59 soft and hard tops were added and model sizes went to 19’ and 21ft. An exciting new cruiser, completely fitted our for weekend outings, was debuted. These were great times.

In 1960 and 1961 sales began to decline, due to the impact of fiberglass boats and the slowing economy. For the second time they built prototype hulls out of fiberglass. The quality of the materials they could buy was not good. None of their craftsmen liked working with the new materials. The methods required were quite opposite of the one they were using. At the New York Boat Show where they had become friends with boat manufacturers all over the country, they found out that some 600 U.S. boat builders had closed their doors. Their larger boats did not sell well. The writing was on the wall. They had done everything they could, but they had to cut the salaries of all employees for 1961. Many cost reductions were made for `62, vinyl decks, pre-manufactured seats, gold flecked steering wheels and different bow treatments but still sales fell.

In December, the final boats were produced, a closeout auction was held, everything left, went to the dump. The buildings and land quickly sold. Ed Hewitt paid every supplier and all the company’s bills. The money from the land and buildings gave the founders a steady income. Fifteen years and fifteen thousand boats were behind them, now. Whirwind boats were the lightest, fastest and most beautiful mahogany boats, – ever made!